-

-

-

- Challenges and Chances: A Review of the 1st Stem Cell Community Day

- Summertime, and the Livin’ Is Easy…

- Follow-on-Biologics – More than Simple Generics

- Bacteria Versus Body Cells: A 1:1 Tie

- Behind the Crime Scene: How Biological Traces Can Help to Convict Offenders

- Every 3 Seconds Someone in the World Is Affected by Alzheimer's

- HIV – It’s Still Not Under Control…

- How Many Will Be Convicted This Time?

- Malaria – the Battle is Not Lost

- Physicians on Standby: The Annual Flu Season Can Be Serious

- At the Forefront in Fighting Cancer

- Molecular Motors: Think Small and yet Smaller Again…

- Liquid Biopsy: Novel Methods May Ease Cancer Detection and Therapy

- They Are Invisible, Sneaky and Disgusting – But Today It’s Their Special Day!

- How Many Cells Are in Your Body? Probably More Than You Think!

- What You Need to Know about Antibiotic Resistance – Findings, Facts and Good Intentions

- Why Do Old Men Have Big Ears?

- The Condemned Live Longer: A Potential Paradigm Shift in Genetics

- From Research to Commerce

- Chronobiology – How the Cold Seasons Influence Our Biorhythms

- Taskforce Microbots: Targeted Treatment from Inside the Body

- Eyes on Cancer Therapy

-

-

-

-

-

- Challenges and Chances: A Review of the 1st Stem Cell Community Day

- Summertime, and the Livin’ Is Easy…

- Follow-on-Biologics – More than Simple Generics

- Bacteria Versus Body Cells: A 1:1 Tie

- Behind the Crime Scene: How Biological Traces Can Help to Convict Offenders

- Every 3 Seconds Someone in the World Is Affected by Alzheimer's

- HIV – It’s Still Not Under Control…

- How Many Will Be Convicted This Time?

- Malaria – the Battle is Not Lost

- Physicians on Standby: The Annual Flu Season Can Be Serious

- At the Forefront in Fighting Cancer

- Molecular Motors: Think Small and yet Smaller Again…

- Liquid Biopsy: Novel Methods May Ease Cancer Detection and Therapy

- They Are Invisible, Sneaky and Disgusting – But Today It’s Their Special Day!

- How Many Cells Are in Your Body? Probably More Than You Think!

- What You Need to Know about Antibiotic Resistance – Findings, Facts and Good Intentions

- Why Do Old Men Have Big Ears?

- The Condemned Live Longer: A Potential Paradigm Shift in Genetics

- From Research to Commerce

- Chronobiology – How the Cold Seasons Influence Our Biorhythms

- Taskforce Microbots: Targeted Treatment from Inside the Body

- Eyes on Cancer Therapy

-

-

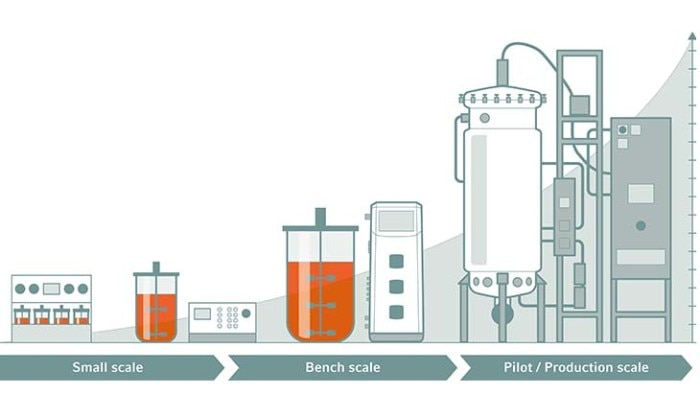

Bioprocessing Scale Up

もっと読む

表示を減らす

Moving to a bioreactor

もっと読む

表示を減らす

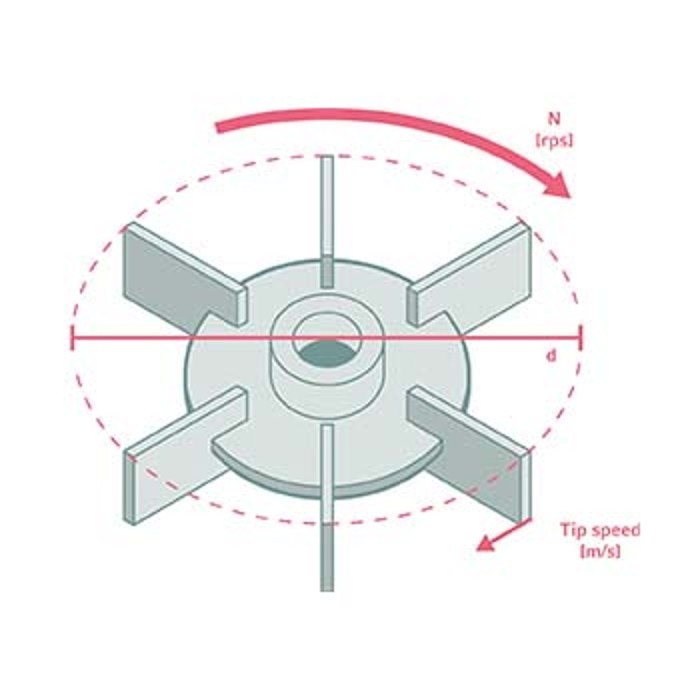

Bioprocess scale up strategies

An established strategy when transitioning to larger working volumes is to monitor and control a single parameter. However, keeping one process parameter constant will change others; therefore, the cells’ growth environment can only be partly reproduced at different scales. Bioengineers must identify the parameters which influence cell growth and productivity most, to decide, which scale up strategy is the most suitable. Although bioprocessing scale up strategies that control several criteria are the most powerful, those that control singular parameters can still be effective, and are historically the most widely used due to their simplicity. Common singular parameters to control include:

Constant power input per liquid volume

- Np: the impeller power number (also known as Newton number),

- ρ: DI water density (kg/m3 ),

- N: agitation speed (rps),

- D: impeller outer diameter (m)

- V: full working volume (m3 ).

もっと読む

表示を減らす

もっと読む

表示を減らす

もっと読む

表示を減らす

Constant tip speed

Definition: The impeller tip speed equals π x d x N, with

- D: impeller outer diameter (m)

- N: agitation speed (rps)

もっと読む

表示を減らす

もっと読む

表示を減らす

Constant kLa

もっと読む

表示を減らす

もっと読む

表示を減らす

もっと読む

表示を減らす

Constant mixing time

もっと読む

表示を減らす

もっと読む

表示を減らす

もっと読む

表示を減らす

Scale-up strategies: recommended resources

- Watch our webinar to find out more about bioprocess scale up strategies and how we scaled-up a cell culture bioprocess from 3 L to 40 L.

- Read in our application note , how we investigated scale up-relevant engineering parameters for differently sized fermentors, including power numbers, tip speed range, and oxygen transfer capabilities.

もっと読む

表示を減らす

Which factors are relevant during bioprocessing scale up?

As depicted above, a tailored scale up strategy is needed to reproduce product yield and quality in an upstream bioprocess across scales. Various other factors need to be considered as well while scaling-up, including space requirements in the lab, staff training, equipment choice, and scaling-up the downstream process. In this panel discussion, industry experts from Eppendorf and other companies share their thoughts on scale up challenges from an economical, operational, and application-related point of view.

Eppendorf products for powerful bioprocessing scale up

- Small-scale: DASbox® Mini Bioreactor System and DASGIP® Parallel Bioreactor Systems

- Bench-scale: SciVario® twin , BioFlo® 120 , BioFlo® 320

- Pilot/production-scale: BioFlo® 510 , CelliGen 510 , BioFlo® 610 , BioFlo® Pro , BioFlo® 720

もっと読む

表示を減らす

Cell culture scale up

- Single-use bioreactors: The BioBLU® c Single-Use Bioreactor portfolio covers working volumes from 100 mL to 40 L. To make the progression from bench-scale to production-scale, the BioFlo® 720 is a bioreactor control system which is compatible with Thermo Scientific™ HyPerforma™ 5:1 Single-Use Bioreactors with working volumes up to 2000 L.

- Glass bioreactors: Eppendorf glass bioreactors for cell culture applications cover working volumes from 60 mL to 10.5 L and are compatible with the small and bench scale Eppendorf bioprocess systems .

- Sterilize in place systems: The CelliGen 510 bioreactor control system covers working volumes from 10.5 L to 32 L.

もっと読む

表示を減らす

Fermentation scale up

- Glass bioreactors: Eppendorf glass bioreactors for microbial applications cover working volumes from 60 mL to 10.5 L and are compatible with the small and bench-scale Eppendorf bioprocess systems .

- Sterilize in place systems: The BioFlo® 510 , BioFlo® 610 and BioFlo® Pro cover working volumes from 16 L to 2400 L.

- Single-use bioreactors: The BioBLU® f Single-Use Bioreactor portfolio covers working volumes from 65 mL to 3.75 L. These stirred-tank bioreactors fully address the specific needs of fermentation. Read more about the scalability of E. coli fermentation in BioBLU® f Single-Use Bioreactors.

もっと読む

表示を減らす

Scalable portfolio

もっと読む

表示を減らす

How our customers use our products

もっと読む

表示を減らす